Metal fabrication collision repairs are a specialized process that restores or enhances damaged metal structures in vehicles, crucial for maintaining structural integrity, safety, and aesthetic appeal. This intricate work involves techniques like welding, cutting, bending, and forming with precise alignment to ensure perfect joints. Choosing professionals with advanced tools is essential for reliable auto body work that improves vehicle performance and looks as good as new. Proper alignment prevents stress concentrations, extends vehicle life, and ensures seamless fits for replacement parts, maintaining overall repair quality. Prioritizing alignment in metal fabrication collision repairs can deliver superior results, fostering customer satisfaction.

In the realm of metal fabrication collision repairs, alignment is more than a technical detail—it’s a game-changer. This article delves into the intricate process of metal fabrication collision repairs, highlighting the critical role alignment plays in achieving precision and quality. By understanding how misalignment impacts repairs, you’ll grasp the benefits of proper alignment for longevity and superior results. Let’s explore why this aspect is indispensable in today’s demanding automotive landscape.

- Understanding Metal Fabrication Collision Repairs

- The Role of Alignment in Repair Process

- Benefits of Proper Alignment for Longevity and Quality

Understanding Metal Fabrication Collision Repairs

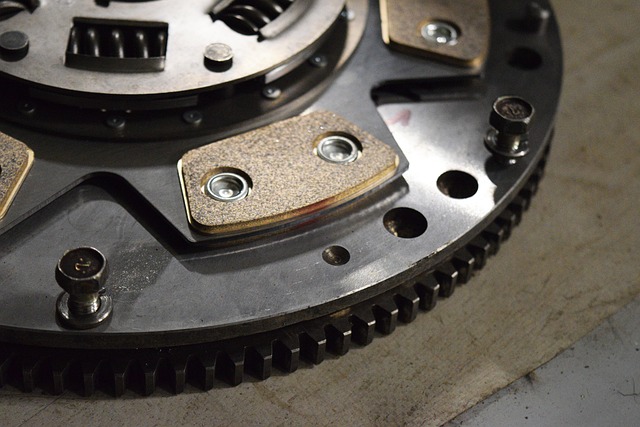

Metal fabrication collision repairs are a specialized process that deals with restoring damaged metal structures to their original condition or even enhancing them. This often involves intricate techniques such as welding, cutting, bending, and forming to create or recreate precise components. In the context of automotive repair, especially at a collision repair center, it’s crucial to understand that metal fabrication is not just about fixing the physical damage; it’s about ensuring structural integrity, safety, and aesthetic appeal.

Auto body work in these cases requires meticulous attention to detail and precision. Every bend, weld, and joint must align perfectly to maintain the vehicle’s structural soundness. This alignment ensures that the vehicle performs optimally and looks as good as new. The process involves a deep understanding of metal properties, as well as the use of advanced equipment to measure and correct any misalignments. Therefore, when seeking automotive repair services, specifically focusing on metal fabrication collision repairs, it’s essential to choose professionals who possess the expertise and tools to deliver precise, safe, and reliable auto body work.

The Role of Alignment in Repair Process

In metal fabrication collision repairs, alignment plays a pivotal role in ensuring the structural integrity and aesthetic quality of the final product. Accurate alignment is crucial throughout the repair process, from assessing damage to welding and painting. Improper alignment can lead to misaligned panels, uneven surfaces, and unsightly gaps or overlaps, compromising both the safety and visual appeal of the vehicle.

A meticulous alignment procedure involves several steps, including measuring and marking critical points, using specialized tools for precision adjustments, and verifying the alignment with advanced technology. This meticulous approach guarantees that every component is correctly positioned, mirroring the original design and manufacturing tolerances. Consequently, a properly aligned repair enhances the overall performance of the vehicle, restores its safety features, and ensures a seamless transition between repaired sections and original factory parts, much like an expert auto detailing service enhances a car’s exterior without altering its underlying structure.

Benefits of Proper Alignment for Longevity and Quality

Proper alignment in metal fabrication collision repairs is paramount for achieving both longevity and quality in the final product. When components are accurately aligned during the repair process, it ensures that all parts of the vehicle—from the frame to individual panels—are correctly positioned relative to each other. This precision prevents stress concentrations, which can lead to future weaknesses and failures, thus extending the life of the repaired vehicle.

Moreover, accurate alignment enhances the overall quality of auto body repair services. It guarantees a seamless fit for replacement parts, minimizing gaps or misalignments that could compromise structural integrity. This meticulous approach not only contributes to the safety and reliability of vehicles but also ensures they maintain their aesthetic appeal, aligning with expectations for top-tier collision repair services. Auto maintenance professionals who prioritize alignment in their processes can deliver superior results, fostering customer satisfaction and retaining business in a competitive market.

In the realm of metal fabrication collision repairs, alignment is not just a step but a cornerstone. As previously mentioned, understanding the intricate dynamics of this process ensures that every repair tells a story of precision and durability. The benefits of proper alignment are clear: it enhances longevity, guarantees quality, and prevents future issues. By aligning metal components with meticulous care, professionals in this field create a symphony of strength and resilience, ensuring that vehicles return to the road not just repaired but upgraded. Thus, prioritizing alignment is a game-changer in maintaining the integrity of metal fabrication collision repairs.